Customised Moulding Services

Moulding is a process of melting raw material and injecting it into a mould or cavity to form a shape. Once the shape is formed, the material is cooled, ejected from the machine and a finished, functional, aesthetically pleasing injection moulded product or part is ready.

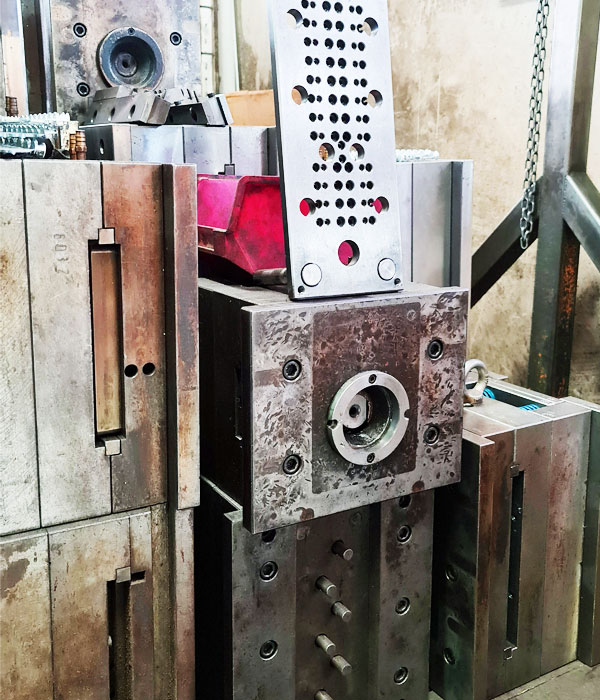

At Myfit, we understand that each furniture is different, and we can manufacture unique metal fittings according to your specification by utilising custom metal moulds. This, in turn, helps optimise cost by allowing production in vast quantities. Our custom metal moulds can cast complex surfaces that can accommodate a wide variety of designs, sizes, and variations. For further information, contact us directly and we are more than happy to assist you further.

The Main Advantages of Moulding

- Repeatability – the same shape can be produced in the millions

- Accuracy – the manufactured product or part is not only repeatable, but can also be produced to a tight tolerance consistently

- Functionality – it is possible to design a number of features into the injection moulded part including complex shapes that cannot be practically achieved by other materials or processes

- Surface finish – with different injection mould processes coupled with specific tooling, a wide spectrum of surface finishes can be achieved, from high gloss to textured surfaces to simulated natural fibres